Hydraulic Machine Controller

This project aims to transform the operational efficiency of hydraulic pressing machines by introducing a Microcontroller Unit (MCU)-based solution. The goal is to semi-automate the pressing process while providing real-time data display and user-customizable pre-settings, significantly enhancing precision, safety, and user interaction.

Core Components:

STM32F4 Series MCU:

An industrial-grade and cost-effective MCU responsible for seamless data acquisition, computational management, and actuation of output devices.

Linear Encoder:

A high-precision digital readout encoder that measures pressure cylinder movement with up to 5µm accuracy.

High Precision Analog-to-Digital Converter (ADC):

Reads data from industrial-grade pressure sensors with high accuracy, crucial for calculating the precise movements of the hydraulic cylinder.

LCD Display:

A compact yet accurate colour display that shows real-time data, enhancing user interaction and machine control.

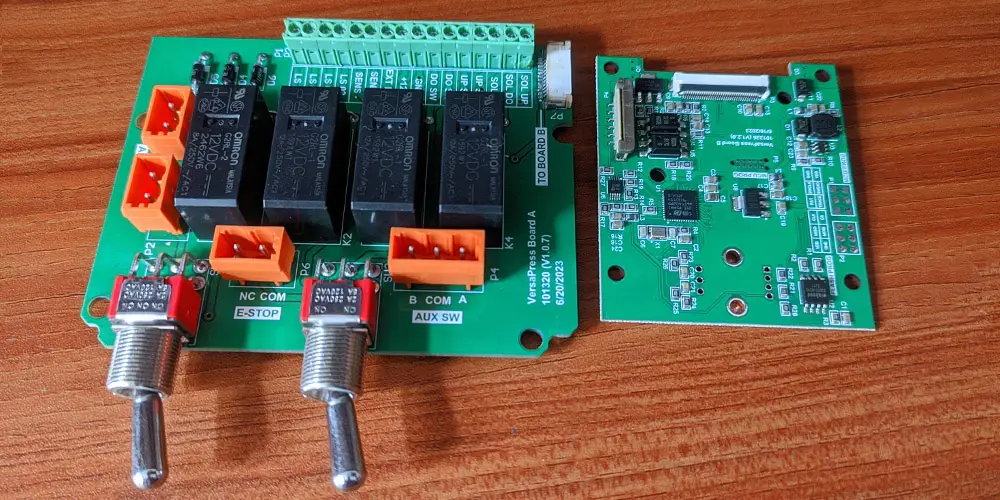

Structural and Circuit Design:

PCB Layout:

The total electronics are efficiently distributed onto two PCBs, labelled as the “Independent Basic Controller Section” and the “Automated Data Handling Section”. This design allows for cost-effective end-products tailored to meet diverse user requirements.

Controller Board Design:

Engineered to handle large currents with a two-layer configuration, optimizing manufacturing costs without compromising functionality.

Data Handling PCB:

Utilizes a four-layer design to implement low-noise, controlled impedance paths, ensuring high-fidelity data processing.

Precise Dimensions and 3D Modelling:

Meticulous layout and component placement, informed by mechanical drawings and 3D modeling, ensure all circuits and components fit perfectly within the machine's enclosure.

Control Systems and Firmware:

Semi-Automation Flexibility:

The device can operate with basic user inputs or, when enhanced programmability and safety features are required, the Automated Data Handling PCB can be seamlessly integrated.

Real-Time Data Display:

Processes and displays crucial operational data with minimal delay, ensuring efficient and safe operation of the pressing machine.

Specialized Firmware with Enhanced Libraries:

Custom-developed firmware maximizes the reliability and performance of this industrial device, leveraging enhanced libraries to optimize system functions.